Introduction

In recent years, the textile industry has witnessed a significant shift towards digital printing technology. As a result, digitally printed fabric has rapidly become the go-to choice for designers and manufacturers alike. With its potential to revolutionize the textile industry, it’s essential to understand what digital fabric printing is, its benefits, and how it’s transforming the market. In this comprehensive guide, not only do we delve into the world of digital fabric printing and its processes, but also cover its uses in the textile industry.

What is Digital Fabric Printing?

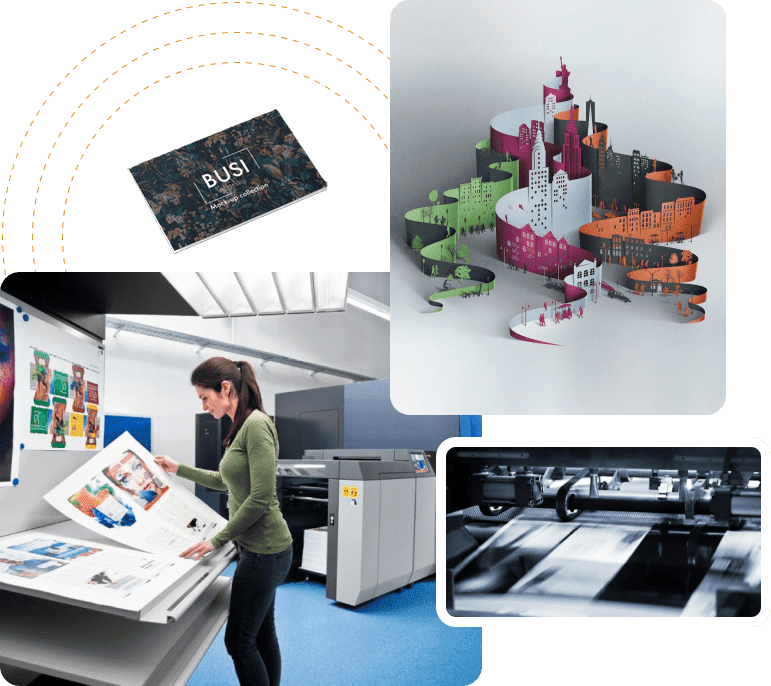

It’s the process of applying digital images or designs directly onto fabric using specialized inkjet printers. This innovative printing technique allows for a high level of detail and color accuracy, making it ideal for creating intricate and vibrant designs on textiles. It has become increasingly popular in the fashion, home décor, and promotional materials sectors due to its cost-effectiveness, speed, and versatility.

Benefits of Digital Fabric Printing

- High-quality prints: Digital fabric printing produces high-resolution images with sharp details and rich colors. This technology allows for accurate color reproduction, ensuring that the final product meets the designer’s vision.

- Cost-effective: With no need for screen setup, digital printing saves on production costs, especially for smaller print runs. This makes it an ideal option for businesses looking to create custom designs and limited edition products.

- Faster turnaround times: Offers quick turnaround times compared to traditional screen printing methods. This makes it perfect for meeting tight deadlines and reducing inventory requirements.

- Sustainable: Reduces water and energy consumption compared to traditional printing methods, making it an eco-friendly option for the textile industry.

- Customization: It’s easy to modify designs, making it a great choice for creating bespoke and personalized products.

The Digital Fabric Printing Process

It involves four key steps:

- Design creation: Designers create digital designs using software like Adobe Photoshop or Illustrator. Therefore, these designs can include intricate patterns, photographs, or illustrations.

- Pre-treatment: The fabric is pre-treated with a special coating to ensure the ink bonds well with the textile fibers, resulting in vibrant and long-lasting prints.

- Printing: The design is printed directly onto the fabric using high-quality, eco-friendly inks. Given that the inkjet printer applies the ink in tiny droplets, it ensures precision and color accuracy.

- Post-treatment: The printed fabric is treated with heat or steam to set the ink, making the print durable and resistant to fading or washing.

Applications of Digital Fabric Printing

Digital fabric printing is widely used in various industries, including:

- Fashion: From high-end runway pieces to ready-to-wear clothing, it’s popular among designers for creating unique and eye-catching garments.

- Home décor: Digitally printed fabric is used for creating customized upholstery, curtains, cushions, and bedding, adding a touch of personality to any living space.

- Promotional materials: Whether it’s tote bags and t-shirts or banners and flags, businesses use digital fabric printing to create branded merchandise, making it an effective marketing tool.

Conclusion

Digital fabric printing is revolutionizing the textile industry with its numerous benefits, including high-quality prints, cost-effectiveness, and sustainability. As this technology continues to evolve, it’s clear that it will become increasingly important in the world of fashion, home décor, and beyond. Whether you’re a designer, manufacturer, or consumer, embracing it is a step towards a more innovative and sustainable future. To learn about the future of textile printing, read our blog Digital Printing Revolutionizing the Textile Industry.